Special Purpose Models

Testing Range

Purpose-built testing systems for specialized applications — from box compression and friction analysis to food texture and fibre testing. Each system engineered with Grade 0.5 accuracy for demanding quality requirements.

Specialized Testing Solutions

Dedicated testing systems for box compression, friction testing, food texture analysis, fibre testing and more specialized applications.

Application-Specific Design

Each special model is engineered for its specific application with optimized test chambers, fixtures, and measurement systems.

Complete India Support

Fully supported by FITCO with local spare parts, comprehensive after-sales service & warranty across India.

Complete Special Purpose Models Range

Dedicated testing systems for specialized applications

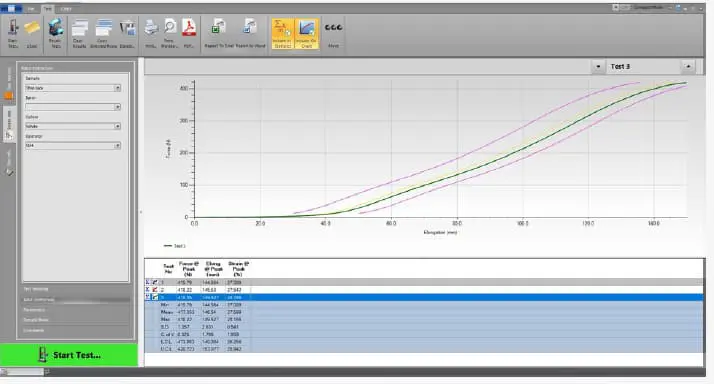

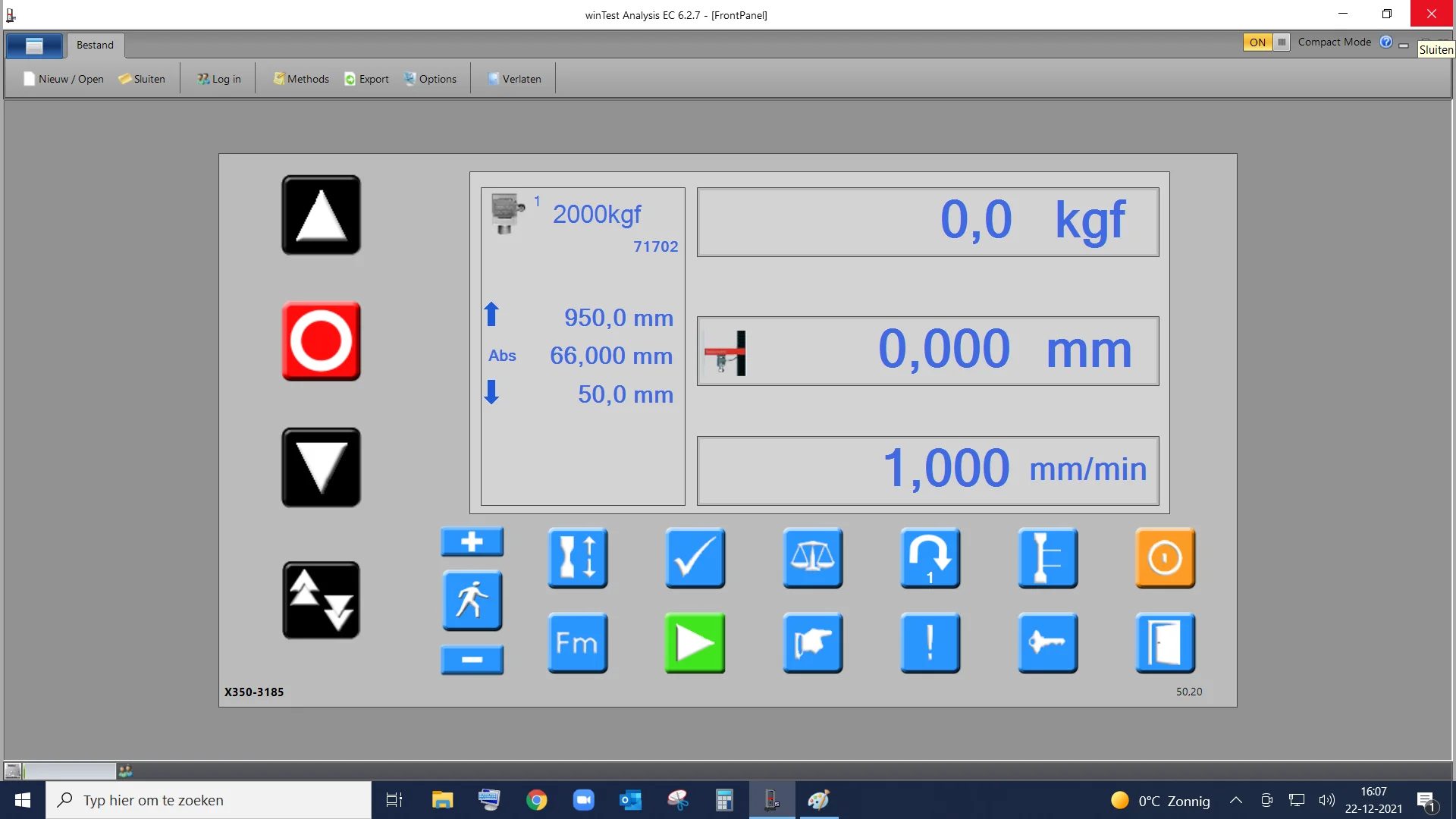

WinTest Software Suite

Comprehensive testing software with 100+ calculation parameters

Advanced Testing

Industry standard test methods with unlimited custom protocols. Automated data storage and easy export to Excel, Word, Access, and SPC systems.

Data Analysis

Real-time graphs, statistical analysis, and professional report generation with comprehensive calculation parameters.

Industry Ready

Pre-configured for aerospace, automotive, construction, metals. Full compliance with international testing standards.

Testing Parameters & Calculations

Comprehensive measurement capabilities for materials testing

Industry Applications

Trusted across diverse industries worldwide