X100 Series

Ultra-Precision Micro-Testing

Compact 1kN universal testing machine engineered for ultra-precision testing of films, fibers, foils and delicate specimens. Ideal for quality control labs with limited space.

Industry Leaders Choose Testometric

X100 Series Details

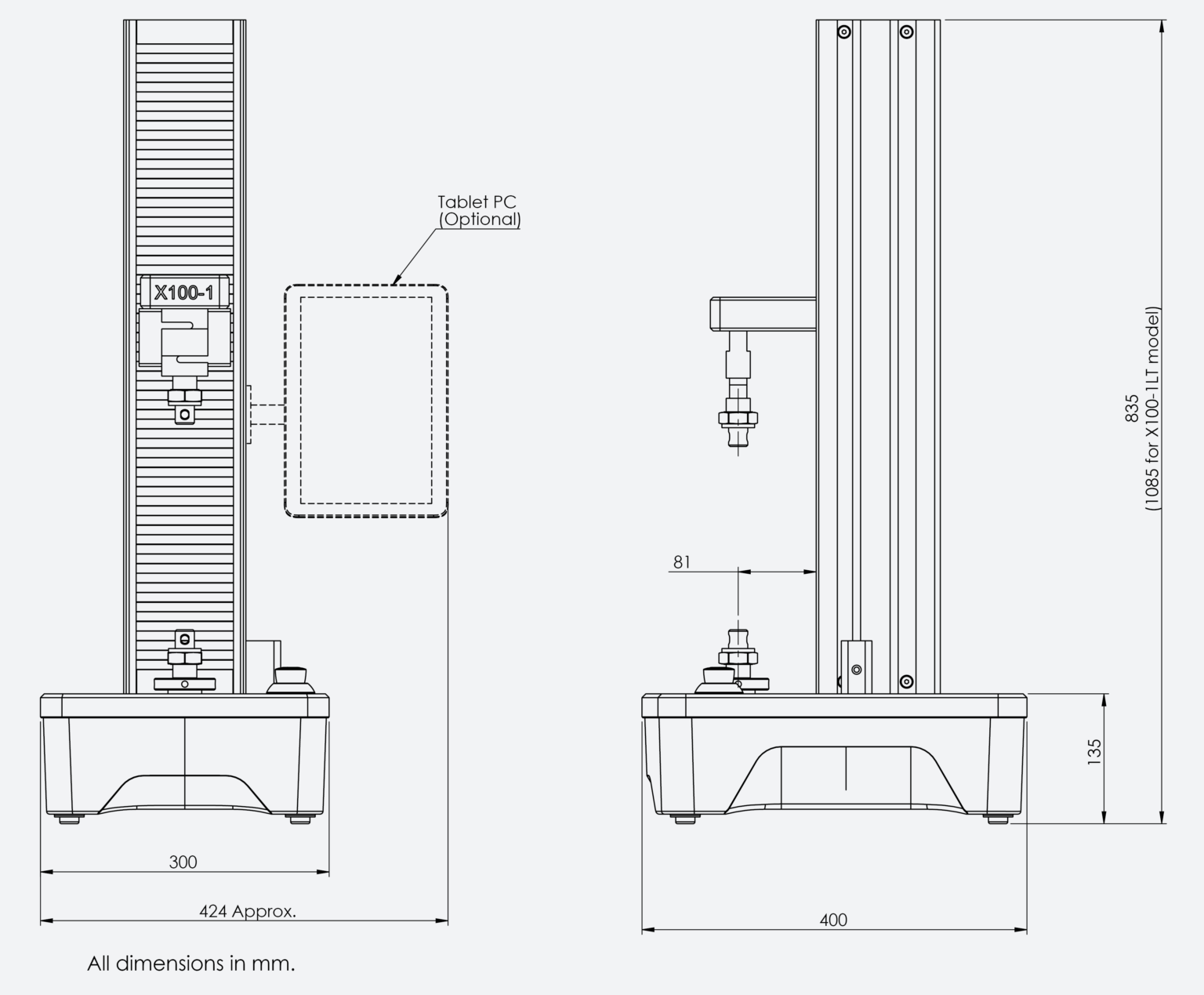

Complete product documentation including technical specifications, high-resolution product views, and dimensional drawings.

Engineered for Micro-Precision

The X100 Series delivers exceptional precision in a compact footprint, perfect for laboratories testing delicate specimens.

Ultra-Precision Testing

Better than ±0.5% accuracy down to 1/1000th of load cell capacity for highly accurate micro-specimen testing.

Compact Footprint

Space-saving single-column design ideal for QC labs, research facilities, and benchtop installations with limited space.

Multiple Load Cells

Wide range of interchangeable load cells from 5N to 1kN with automatic recognition for versatile testing capabilities.

AC Servo Drive

Digital AC servo system with brushless motor provides maintenance-free operation with exceptional speed control accuracy.

winTest™ Software

Complete testing software suite included at no extra cost with extensive test methods and report generation capabilities.

Overload Protection

800% capacity overload protection safeguards load cells from accidental damage during setup and testing operations.

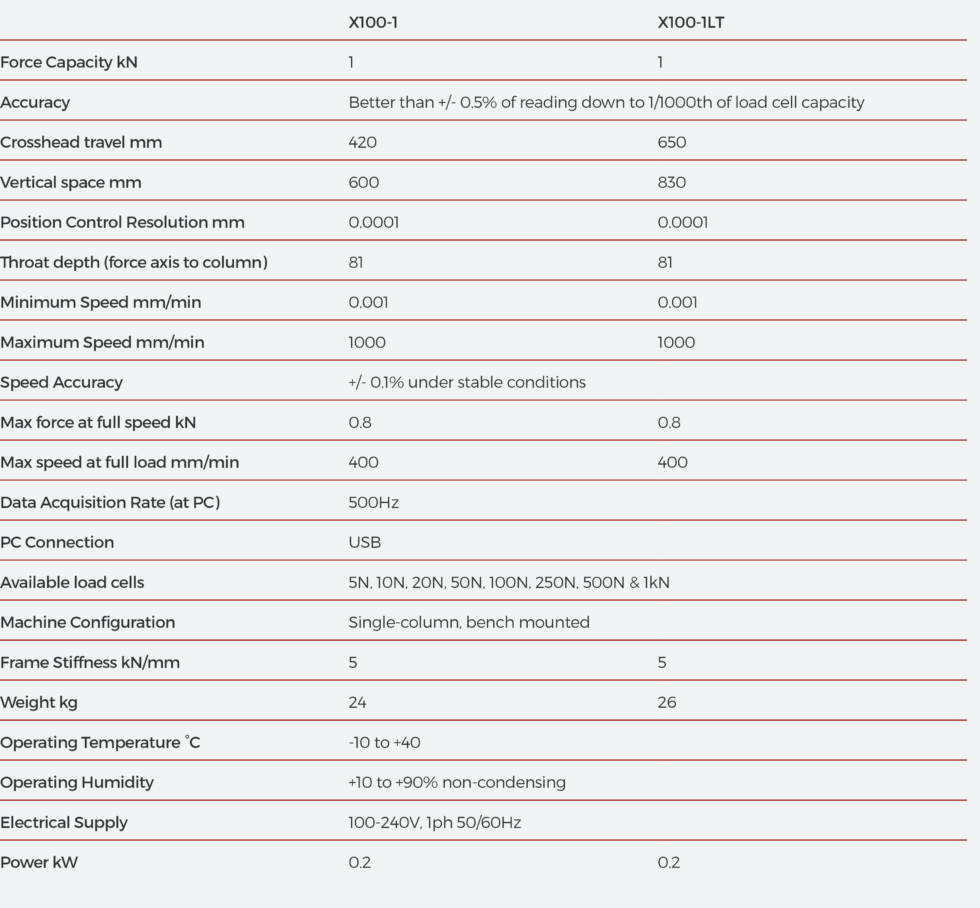

Full Specifications

Available in standard (X100-1) and long-travel (X100-1LT) variants to match your testing requirements.

| Specification | X100-1 | X100-1LT | What This Means |

|---|---|---|---|

| Force Capacity | 1 kN (225 lbf) | 1 kN (225 lbf) | Test films, fibers, adhesives up to ~100 kg force |

| Load Measurement Accuracy | Better than ±0.5% of reading down to 1/1000th of load cell capacity | Reliable for ISO/ASTM compliance testing | |

| Crosshead Travel | 420 mm | 650 mm | LT model for high-elongation materials like rubber |

| Vertical Test Space | 600 mm | 830 mm | Room for grips, extensometers, chambers |

| Position Resolution | 0.0001 mm | Detect movements 1000× thinner than hair | |

| Throat Depth | 81 mm | Wide samples up to 162mm between grips | |

| Speed Range | 0.001 - 1000 mm/min | From creep tests to high-speed peel tests | |

| Speed Accuracy | ±0.1% under stable conditions | Consistent strain rates for repeatable results | |

| Max Force at Full Speed | 0.8 kN | High-speed testing at 80% capacity | |

| Max Speed at Full Load | 400 mm/min | Full force available at standard test speeds | |

| Data Acquisition Rate | 500 Hz | Captures 500 data points/second for sharp peaks | |

| PC Connection | USB | Simple plug-and-play with any Windows PC | |

| Available Load Cells | 5N, 10N, 20N, 50N, 100N, 250N, 500N & 1kN | 8 options from delicate fibers to tough films | |

| Frame Stiffness | 5 kN/mm | Minimal frame deflection for accurate strain | |

| Machine Configuration | Single-column, bench mounted | Fits on standard lab bench (60×60cm) | |

| Weight | 24 kg | 26 kg | Portable, easy to relocate within lab |

| Operating Temperature | -10°C to +40°C | Works in most lab environments | |

| Operating Humidity | +10% to +90% non-condensing | Suitable for Indian monsoon conditions | |

| Electrical Supply | 100-240V, 1ph 50/60Hz | Works worldwide, no transformer needed | |

| Power Consumption | 0.2 kW | Low energy, no special wiring required | |

Ready to Upgrade Your Testing Capabilities?

Get a customized quote with load cells and grips tailored to your applications.

Real-World Testing Solutions

The X100 Series excels in testing lightweight, delicate materials with traceable accuracy to international standards.

Flexible Packaging Films

Tensile strength, elongation, and seal strength testing of BOPP, PET, PE, and laminated pouches for food packaging quality control.

Textile Fibers & Yarns

Single fiber tensile testing for cotton, polyester, nylon yarns measuring breaking force and elongation for spinning quality verification.

Adhesives & Tapes

Peel strength, lap shear, and 90°/180° peel testing for pressure-sensitive adhesives, medical tapes, and industrial bonding verification.

Rubber & Elastomers

Tensile, tear strength, and compression testing of thin rubber sheets, O-rings, gaskets, and silicone components for automotive seals.

Paper & Tissue Products

Tensile index, burst strength, and wet tensile testing of tissue paper, napkins, and corrugated board for packaging compliance.

Medical Devices

Catheter burst testing, suture pull-out strength, and medical tubing tensile testing for FDA/CE compliance documentation.

The X100 has transformed our film testing workflow. The compact size fits perfectly in our QC lab, and the ±0.5% accuracy gives us confidence in our results. Setup time has been reduced significantly with the automatic load cell recognition.