LMI5500 Series

Melt Flow Indexer

A modern melt flow indexer for accurate MFR/MVR testing (ASTM D1238 / ISO 1133) and solvent-free Intrinsic Viscosity (IV) Method B testing to ASTM D4603. Built for polymer processors and PET recyclers who need repeatable results, fast workflows, and traceable data.

Ideal for PET recycling & rPET quality: Reliance Industries, Starlinger, and EREMA-style recycling operations where IV consistency and degradation monitoring matter.

Temperature Stability

High precision control

Method B

ASTM D4603 (no solvents)

ASTM/ISO

D1238 + ISO 1133

Trusted By

Industry Leaders Worldwide

Intrinsic Viscosity (IV) Method B — No Solvents

Perform ASTM D4603 Intrinsic Viscosity Method B testing without the use of any solvents or chemicals, while maintaining the same robust MFR/MVR workflow used for daily QC.

Made for PET recyclers and processors

The LMI5500 Series helps teams qualify recycled PET quality, monitor polymer degradation, and keep extrusion and bottle-grade rPET production consistent using fast, repeatable IV correlation and melt flow testing.

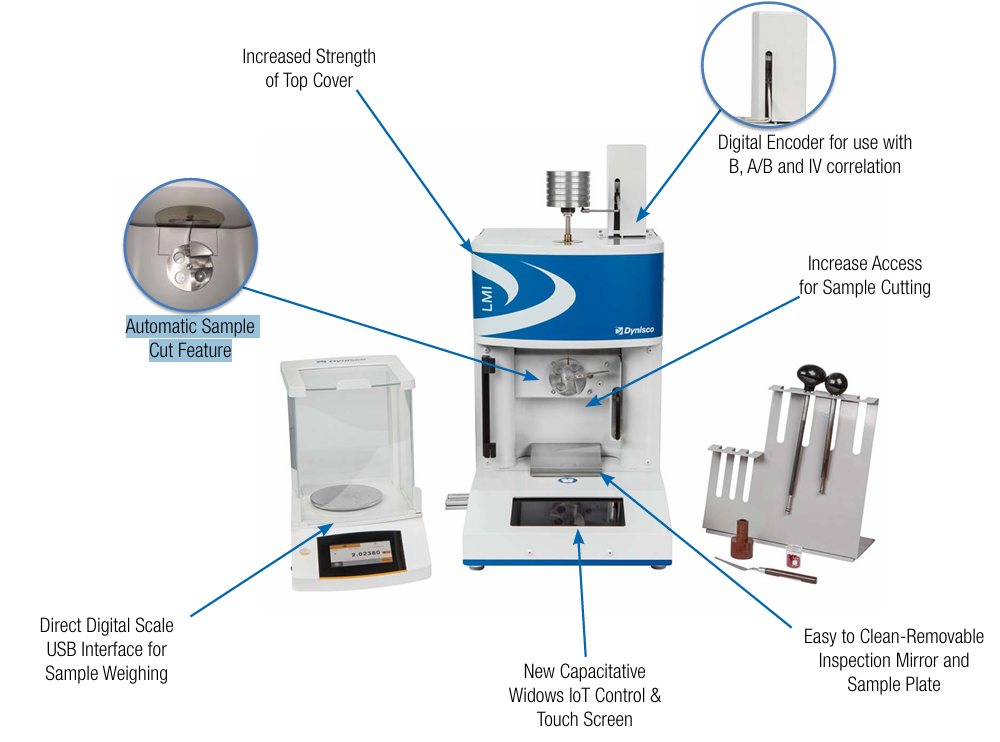

- ASTM D4603 Method B IV: run IV Method B testing without solvents/chemicals.

- Digital encoder support: built for Method B, A/B testing, and IV correlation.

- Automatic sample cut feature: improves sample consistency and throughput.

- Better access for sample cutting: ergonomic layout for day-to-day QC use.

- Direct digital scale USB interface: streamlined sample weighing and traceability.

- Windows IoT capacitive touchscreen: clear operation with modern UI.

LMI5500 Series Demonstrations

Watch common test workflows and best practices for the Dynisco LMI5500 series.

Accurate MFR/MVR + Solvent-Free IV Testing

The LMI5500 Series supports melt flow analysis and intrinsic viscosity correlation to help you qualify polymer lots, monitor degradation, and keep processing consistent.

Intrinsic Viscosity (IV) Method B

Perform IV Method B testing to ASTM D4603 without solvents or chemicals—ideal for PET recyclers needing precise IV measurement for assessing recycled PET quality.

Melt Flow Rate (MFR) & Melt Volume Rate (MVR)

Comprehensive melt flow analysis beyond standard tests to evaluate processability and lot-to-lot consistency of PET and other polymers.

Degradation Monitoring

Track polymer degradation and material consistency to support high-quality recycling and stable processing conditions for large-scale operations.

Key Advantages

Windows 10 IoT Touchscreen

New Windows 10 IoT touch interface designed for fast workflows, clear results display, and straightforward method setup.

Automatic Sample Cutter

Automatic cutting improves ease and consistency in sample preparation, supporting repeatable tests and better throughput.

Connectivity Built In

Built-in WiFi and Ethernet plus HDMI and multiple USB ports for flexible data export, peripherals, and integration.

Direct Digital Scale Interface

USB interface for direct sample weighing, helping improve traceability and reducing manual transcription errors.

Dynisco LMI5500 vs ZwickRoell, Instron/CEAST, and GÖTTFERT

If you’re evaluating melt flow indexers (MFI testers / extrusion plastometers) like ZwickRoell Cflow/Mflow/Aflow, Instron/CEAST MFi5/MFi7 (MF20/MF30/MF50), or GÖTTFERT mi-series, this section highlights what matters for real-world polymer QC—especially PET & rPET quality control.

The Dynisco Advantage While general-purpose testing equipment manufacturers offer melt flow indexers, the Dynisco LMI5500 is purpose-built for the polymer processing and recycling industry—delivering faster ROI, specialized PET features, and a workflow designed for the factory floor, not just the research lab. Proven at scale: 50+ units deployed at India's leading polymer facilities as platinum standard QC equipment.

| Decision Factor | Dynisco LMI5500 | General Material Testers (ZwickRoell / Instron / GÖTTFERT) |

|---|---|---|

| Primary Focus Who is it built for? |

Polymer Processors & Recyclers. Designed specifically for production QC, rPET verification, and plant-floor reliability. |

General Material Labs & R&D. Broad testing focus often results in over-complex software and slower workflows for daily QC. |

| PET/rPET Value (IV Testing) Solvent-free Method B |

Native & Integrated. Offers correlated IV Method B testing directly on the touchscreen—no hazardous solvents, no external PC required. |

Often Lacking or Complex. IV correlation typically requires expensive optional software or isn't a core focus of their general plastometer lines. |

| User Experience Interface & Ease of Use |

Modern Windows 10 IoT. Familiar, smartphone-like touch interface. Zero learning curve for operators. Built-in WiFi/USB connectivity. |

Legacy or Proprietary. Often relies on older interfaces, complex "university-style" software, or expensive PC tethering for full functionality. |

| Cost of Ownership Features vs. Price |

All-Inclusive Value. Includes digital scale interface, auto-cutter options, and multiple standards support without hidden "module" costs. |

Module-Based Pricing. Key features often sold as expensive upgrades (auto-cutting, software licenses, specific weights) driving up total cost. |

| Support Expertise | Polymer Process Experts. Dynisco lives in the extrusion plant. We understand pressure, temperature, and flow better than generalists. |

Generalists. Their expertise is spread across metals, composites, and universal testing—diluting their focus on unique polymer challenges. |

Why LMI5500 is the smart choice for PET & polymer QC

When you compare melt flow index testers across brands, the best choice is the one that improves repeatability, reduces operator steps, and supports the tests your customers demand.

One platform for MFR/MVR + IV Method B

Run day-to-day melt flow testing and solvent-free IV Method B (ASTM D4603) workflows in a single system—useful when your PET/rPET quality program needs both melt flow and IV correlation.

Built for high-throughput QC teams

Features like automatic sample cutting and direct scale interface are aimed at repeatable workflows and fewer manual steps in routine polymer QC.

Modern interface + connectivity

Touchscreen operation with built-in connectivity options supports traceable reporting and easier day-to-day operation compared to older, PC-tethered workflows.

Designed for PET recycling realities

For PET recyclers, IV consistency and degradation monitoring can be as important as melt flow. LMI5500 is positioned to support that PET-focused QA mindset.

Built for Global Test Methods

Performance meets major international standards used in polymer QC and R&D.

ASTM D1238 / ISO 1133

Supports melt flow testing procedures with repeatable MFR/MVR reporting aligned to widely adopted polymer testing standards.

ASTM D4603 IV Method B

Solvent-free IV Method B workflow supports PET recyclers and processors who need fast, reliable IV correlation for rPET quality.

Multi-Standard Compatibility

Meets requirements across ASTM D3364, BS2782, DIN 53735, and JIS K7210 (as applicable to melt flow testing practices).

Designed for Daily Use

Improved die access for cutting, a strategically placed mirror for visibility of the die area, and nearly unlimited program storage for routine operations.

Performance Characteristics

Detailed performance and configuration data for the LMI5500 Series base model.

Performance Characteristics

Dimensions

Electrical Specifications

Melt Flow Index Tester (MFI) FAQs

Quick answers for teams comparing Dynisco LMI5500 with melt flow indexers from Instron/CEAST, ZwickRoell, or GÖTTFERT.

Is LMI5500 suitable if I’m searching for an “Instron melt flow index tester” or “CEAST MFi7” alternative?

If your requirement is standard MFR/MVR testing to ASTM D1238 / ISO 1133, LMI5500 fits the same core use case (melt flow index / extrusion plastometer workflows). If you also need PET-focused solvent-free IV Method B testing (ASTM D4603), LMI5500 can be a strong fit to evaluate.

Does LMI5500 support both MFR and MVR?

Yes—LMI5500 is positioned for MFR/MVR melt flow testing aligned to ASTM D1238 and ISO 1133 methods, supporting routine polymer QC reporting.

What is “IV Method B” and why does it matter for PET recyclers?

Intrinsic Viscosity (IV) Method B (ASTM D4603) is a solvent-free approach often used by PET recyclers and processors for IV correlation and quality monitoring. It can help teams track degradation and maintain consistent rPET quality.

Which competitors should I compare against when buying a melt flow indexer?

Common families include ZwickRoell Cflow/Mflow/Aflow, Instron/CEAST MFi (and MF series), and GÖTTFERT mi-series. The best comparison is based on your required standards, automation level, throughput, and whether you need PET-specific IV Method B workflows.

Need Reliable IV & MFI Results?

Tell us your polymer type, standards, and throughput requirements. We’ll recommend the right LMI5500 configuration, accessories, and training for your lab or plant QC workflow.