ISO 527-3 – Tensile Testing of Plastic Films

Your comprehensive guide to ISO 527-3 testing of plastic films and sheets, including specimen preparation, grip selection, video extensometry, test procedures, and data analysis – optimized for Testometric UK universal testing machines.

Overview

ISO 527-3 specifies test conditions for determining tensile properties of plastic films and sheets typically 1-4mm thick. This standard addresses the unique challenges of testing thin materials including proper specimen preparation, gentle gripping, and accurate strain measurement using video extensometry. Key outputs include tensile strength, modulus, elongation at break, and stress-strain behavior.

Tip: Video extensometry is essential for accurate strain measurement in films. Use gentle clamping pressure to avoid damaging thin specimens while ensuring no slippage occurs.

Industries & applications

ISO 527-3 is critical for industries utilizing plastic films and thin sheets. Different applications require specific properties for optimal performance.

Packaging

Food films, barrier films: PE, PP, PET, PA. Critical for puncture resistance, seal strength, and barrier properties during processing and transport.

Agricultural films

Greenhouse covers, mulch films: LDPE, EVA. Focus on UV resistance, tear strength, and flexibility under environmental stress.

Medical packaging

Sterile barriers, pouches: PET, Tyvek. Combination of strength, puncture resistance, and maintained integrity after sterilization.

Industrial films

Protective films, release liners: PU, silicone. Balance of adhesion, removability, and mechanical strength for specialized applications.

Common pitfalls

- Specimen damage during preparation: Use sharp cutting tools and templates; avoid stretching or heating films during cutting.

- Grip damage: Use appropriate jaw faces (rubber or soft materials) with minimal clamping force; check for crushing or stress concentrations.

- Inaccurate strain measurement: Ensure video extensometer has sufficient resolution and contrast markers are properly applied.

- Environmental sensitivity: Control temperature and humidity; many films are hygroscopic and properties change with moisture content.

- Anisotropic behavior: Test both machine and transverse directions as film properties often differ significantly between orientations.

- Necking effects: Monitor for localized necking that can affect strain measurement accuracy, especially in oriented films.

Quick win: Always condition specimens in controlled environment and use video extensometry to capture true strain behavior throughout the test.

Specimens & preparation

- Specimen geometry: Type 2 specimens (25mm wide × 150mm overall length) for films 1-4mm thick

- Cutting: Use sharp dies or precision cutters to avoid edge defects; ensure parallel sides and smooth edges

- Conditioning: Stabilize at 23°C ± 2°C, 50% ± 5% RH for minimum 4 hours (longer for thick films)

- Directional testing: Test both machine direction (MD) and transverse direction (TD) for oriented films

- Surface marking: Apply contrast markers for video extensometry if required

Grip selection

- Pneumatic grips with soft jaw faces (rubber or polymer coated) to prevent specimen damage

- Low clamping pressure: Sufficient to prevent slippage without crushing or stress concentrations

- Wide grip area: Distribute clamping stress over maximum possible area

- Anti-slip measures: Use textured grips or capstan-type arrangements for very thin films

Video extensometry

- Non-contact measurement: Essential for thin films to avoid influencing test results

- High resolution: Sufficient to capture small strains accurately (typically 0.01% strain resolution)

- Gauge length: Typically 50mm for Type 2 specimens, adjusted based on expected elongation

- Marker tracking: Ensure good contrast and stable lighting for reliable marker detection

- Calibration: Regular calibration using certified gauge blocks

Procedure

- Measure specimen thickness at multiple points; record minimum value for calculations.

- Install specimen in grips with minimal clamping force; verify no damage or stress concentrations.

- Set up video extensometer with appropriate gauge length and marker recognition.

- Apply test at specified rate (typically 1-50 mm/min); monitor for slippage or necking.

- Record complete stress-strain curve until specimen failure or specified elongation.

Calculations

- Tensile strength: Maximum stress = F_max / (width × thickness)

- Modulus: Slope of stress-strain curve in linear region (typically 0.05% to 0.25% strain)

- Elongation at break: (Final gauge length - Initial gauge length) / Initial gauge length × 100%

- Energy to break: Area under stress-strain curve (toughness)

Reporting

- Specimen details: dimensions, thickness variations, conditioning history

- Test parameters: grip type, clamping force, test speed, extensometry method

- Environmental conditions: temperature, humidity during testing

- Directional results: separate reporting for MD and TD properties if applicable

- Statistical analysis: mean, standard deviation, coefficient of variation for all properties

Recommended Testometric setup

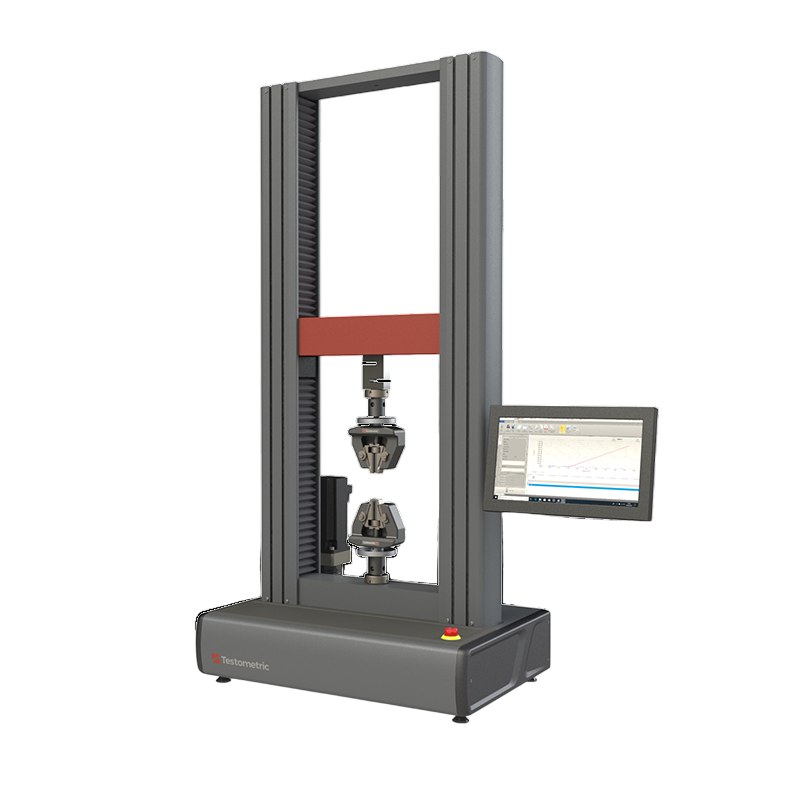

Testing machine

Testometric X-Series (X250/X350) with 2.5–10 kN capacity; precise crosshead control optimized for the lower forces typical in film testing.

Gripping system

Pneumatic film grips with soft rubber jaw faces; pressure regulation to minimize specimen damage while preventing slippage.

Video extensometry

High-resolution video extensometer with automatic marker tracking; essential for accurate strain measurement in thin films.

Software

WinTest Analysis with pre-configured ISO 527-3 methods; automatic calculation of all required properties and directional testing protocols.

- ±0.5% system accuracy; 0.000001 mm position control resolution for delicate films.

- High-rate data acquisition (500/1000 Hz) to capture yield, necking, and break precisely.

- 800% load cell overload protection and a wide grip catalog to prevent slippage.

- FITCO India support: install, training, spares, after-sales, 2-year comprehensive warranty.

Model suggestions for thin films

| Model (X-Series) | Capacity | Typical use |

|---|---|---|

| X250-2.5 | 2.5 kN | Very thin films; delicate specimens; education labs |

| X250-5 | 5 kN | General packaging films and laminates |

| X350-10 | 10 kN | Thicker films, tapes, and multi-layer structures |

| Accessory | Option | When to choose |

|---|---|---|

| Grips | Pneumatic film grips, rubber-faced jaws | Minimize slippage on thin/weak films |

| Jaws | Wide jaws (50–75 mm) | Reduce edge stress concentrations |

| Strain | Video/non-contact extensometer | High elongation, necking, or thin opaque films |

Configuration varies by film type and thickness; FITCO can recommend a validated ISO 527-3 kit.

FAQs

Why video extensometry?

Contact extensometers can influence thin film behavior. Video provides non-contact measurement preserving natural specimen response.

MD vs TD testing?

Oriented films exhibit different properties in machine (MD) and transverse (TD) directions; both should be tested for complete characterization.

Grip pressure optimization?

Start with minimal pressure and increase incrementally until no slippage occurs; excessive pressure causes stress concentrations and premature failure.

Thickness measurement?

Measure at multiple points due to typical thickness variations in films; use minimum thickness for stress calculations per ISO 527-3.

Need Help with Film Testing?

Our experts can help you select the right Testometric UTM configuration, film grips, and video extensometry for your plastic film and sheet testing requirements.