ISO 37 – Tensile Testing of Rubber

Your comprehensive guide to ISO 37 dumbbell specimens, die types, grip selection, strain measurement, test speeds, calculations, and reporting – centered on Testometric UK universal testing machines.

Overview

ISO 37 specifies the determination of tensile stress–strain properties of rubber and thermoplastic elastomers. Key outputs include tensile strength, elongation at break, and stress at defined elongations (e.g., M100, M200). Reliable results depend on correct die type, grip choice, strain measurement, and control of test rate and environment.

Tip: For highly extensible materials, prefer video extensometry to avoid contact with the gauge section. Ensure clear marker tracking and adequate lighting.

Industries & material

ISO 37 underpins tensile characterization across a wide range of rubber and elastomer applications. Below are common sectors and typical materials you may encounter, with notes relevant to testing.

Automotive

Seals, hoses, mounts: NR, SBR, NBR, EPDM, FKM. Watch heat build-up in jaws at long pulls; use appropriate jaw faces to prevent cutting.

Medical & pharma

Silicone (VMQ) and TPEs (TPV, TPE-S). Control environment tightly and use clean jaw faces to avoid contamination or surface damage.

Consumer & footwear

EVA, TPU, TPE blends. For highly extensible grades, prefer non-contact video extensometry and ensure long travel and adequate frame height.

Oil & gas/chemical

FKM, HNBR, FFKM. Specimens may be conditioned in media; document exposure and time-in-media as it affects modulus and elongation.

Common pitfalls

- Grip breaks and notch effects: Ensure smooth dumbbell edges and correct clamping pressure; reject breaks at or near the grip per ISO rules.

- Slippage at high strains: Use pneumatic grips with compliant faces and verify with ink marks; increase pressure in small steps to avoid cutting.

- Incorrect gauge length: Set and verify initial marker spacing per die type; re-check after mounting as rubber can creep under clamp load.

- Rate mismatches: Program speeds to achieve the specified strain rate range; consider segmented ramps for very extensible materials.

- Extensometer out-of-range: Choose a device with sufficient travel; switch to video extensometry beyond clip-on limits to avoid loss of strain data.

- Environmental drift: Temperature and humidity shift modulus; document conditions and stabilize specimens before testing.

Quick win: Standardize a short pre-test checklist (die type, gauge length, pressure, extensometer range, speed) – it eliminates most re-tests.

Specimens & die types

- Die types: Select per ISO 37 Type 1/2/3/4 based on thickness and application; maintain dimensional tolerances meticulously.

- Conditioning: Stabilize specimens at specified temperature/humidity; record dwell time and actual conditions.

- Surface quality: Smooth edges to avoid notch sensitivity; avoid talc or lubricants in the gauge section.

- Replicates: Test =5; more for materials with high variability.

Grip selection & jaw faces

- Pneumatic grips with pressure control help maintain constant clamping during large elongations.

- Jaw faces: rubber-coated or serrated as appropriate; avoid cutting into the specimen ends.

- Use anti-slip markers to detect movement and adjust pressure accordingly.

Instrumentation & extensometry

- Load cell sized for expected forces (operate in 10–90% range).

- Extensometry: video extensometer recommended for high elongations; clip-on options for moderate strains.

- Gauge length: set per die type; verify marker spacing pre-test.

Rates, speeds & gauge length

Program crosshead speeds to achieve the required strain rates. For very extensible rubbers, use segmented speeds or ramps to capture the full curve without losing resolution at low strains.

Quick setup checklist

Specimen

Correct die type, dimensions verified, smooth edges, conditioned per plan.

Grips

Pneumatic pressure set; jaw faces selected; anti-slip marks placed.

Instrumentation

Load cell in range; extensometer/video set for expected strain; sampling rate set.

Method

Gauge length confirmed; speed/strain rate programmed; environment recorded.

Procedure

- Measure specimen dimensions and set gauge length markers.

- Install grips and set clamping pressure; perform a trial pull to verify no slip.

- Zero load and strain; start test and record force–elongation continuously.

- Stop at break; record break location (gauge vs. grip) and necking observations.

Calculations

- Tensile strength at break (force divided by original cross-sectional area).

- Elongation at break and at specified stresses (M100/M200 etc.).

- Modulus values at defined elongations from the stress–strain curve.

Reporting

- Die type, dimensions, conditioning, gauge length.

- Grip type, jaw faces, and pressure settings.

- Extensometer type, strain range, sampling rate.

- Results: strength, elongation, modulus points; curves; n, mean, SD; outlier handling.

QA, verification & uncertainty

Verify load cell, extensometer calibration, and rate accuracy at planned intervals. Maintain uncertainty budgets and method locks. Run periodic proficiency checks.

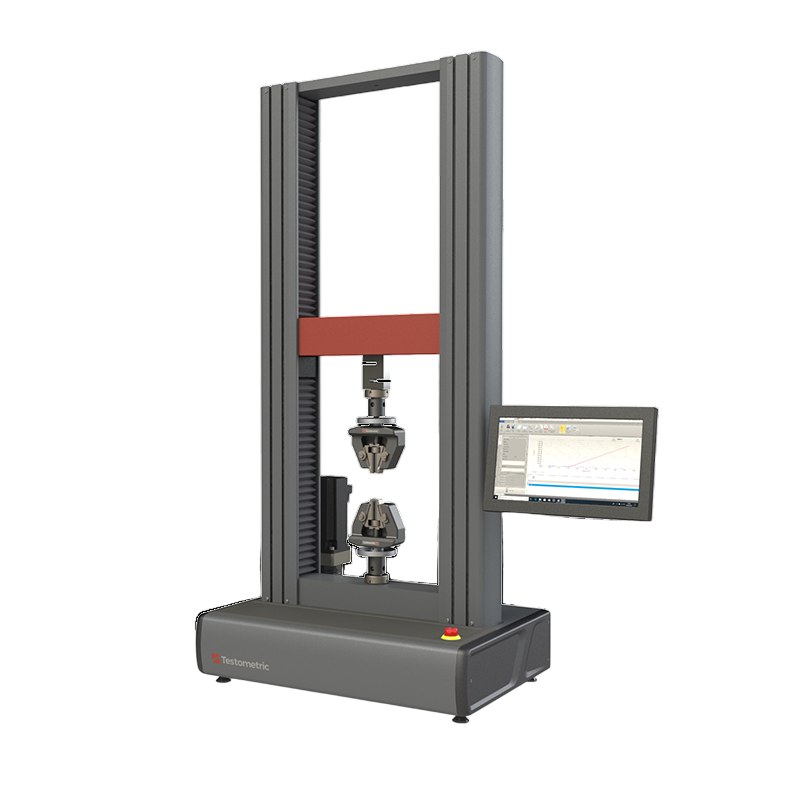

Recommended Testometric setup

Frame & capacity

Testometric twin-column UTM with suitable load cell for elastomer testing; high-resolution controller and long crosshead travel for high elongations.

Grips & jaw faces

Pneumatic grips with rubber-faced jaws or serrated faces as applicable; precise pressure control to avoid slip without cutting.

Extensometry

Video extensometer recommended for large strains; clip-on extensometers for small-to-moderate elongations with quick attach/release.

- ±0.5% accuracy and 0.000001 mm position control resolution for consistent modulus points (M100/M200).

- High-rate acquisition (500/1000 Hz) to capture yield and break on fast-stretch rubbers.

- 800% overload protection; extensive grip and jaw face catalog to prevent slip or cutting.

- FITCO India: install, training, spares, after-sales, and a 2-year comprehensive warranty.

Model suggestions for ISO 37

| Model | Capacity | Typical use |

|---|---|---|

| X350-10 | 10 kN | General rubber compounds; education/QC |

| X500-25 | 25 kN | Higher-strength rubbers; longer gauge lengths |

| X250/X350 | 25/35 kN | Twin-column frames for higher stiffness and long travel |

| Accessory | Option | When to choose |

|---|---|---|

| Grips | Pneumatic with rubber-faced jaws | High elongations; minimize slip without cutting |

| Grips | Serrated/Toothed jaws | Tough compounds where slip persists (watch for edge damage) |

| Strain | Video extensometer | Large elongations beyond clip-on travel |

Configurations vary by compound and die type; FITCO can supply a validated ISO 37 kit with grips and extensometry.

FAQs

How many specimens?

At least five; increase count for high-variability compounds or multiple die types.

Grip slip at high elongation?

Increase pneumatic pressure incrementally, switch jaw faces, or shorten clamping length; verify with ink marks.

Extensometer choice?

Use non-contact video for elongations above clip-on range to avoid gauge interference and slippage.

Need Help with ISO 37 Rubber Testing?

Our experts can help you select the right Testometric UTM configuration, rubber grips, and extensometry for your elastomer testing requirements.