ISO 178

ISO 178 – Flexural Properties of Plastics

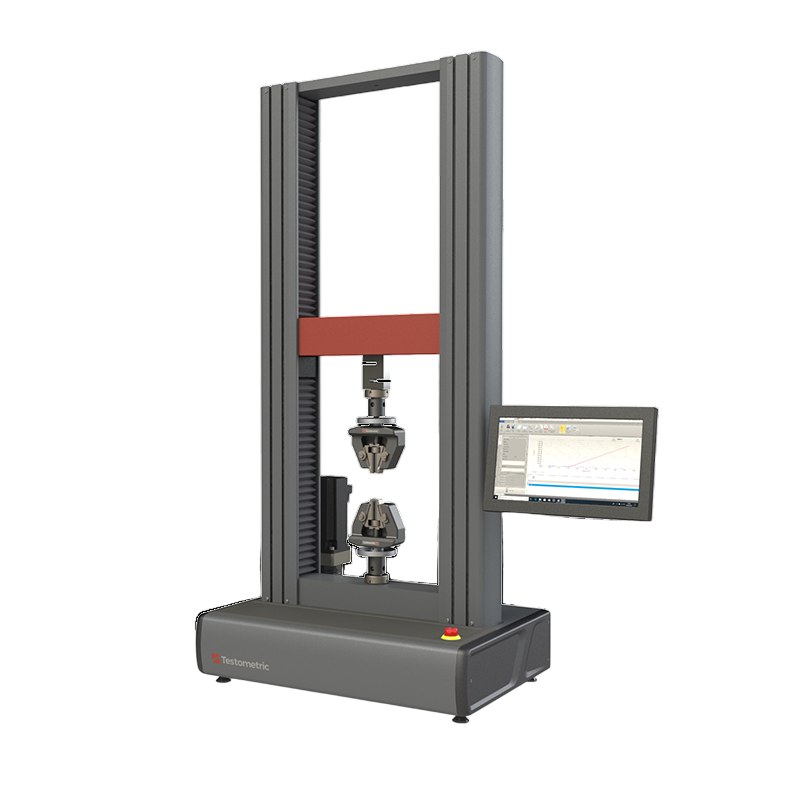

A complete, practical guide to three-point bending: span selection, deflection measurement, calculations, and reporting – built around Testometric UK universal testing machines and fixtures.

Related Standards

ISO Standard

ISO 527-2

Tensile testing of rigid plastics – complementary to flexural for complete characterization.

ASTM Standard

ASTM D790

US equivalent for flexural testing – key differences in span and speed requirements.

ISO Standard

ISO 180

Izod impact testing – combined with flexural for toughness assessment.

Need Help with ISO 178 Flexural Testing?

Our experts can help you select the right Testometric UTM configuration, flexural fixtures, and deflection measurement for your specific plastic testing requirements.