ASTM D575-91 – Compression Testing of Rubber Properties

A practical, lab-ready guide to specimens, platens, alignment, strain measurement, rates, and analysis – purpose-built for Testometric UK universal testing machines and supported by FITCO India.

Overview

ASTM D575-91 specifies methods to determine the compressive stress–strain behavior of rubber and elastomeric materials. Typical outputs include compressive modulus in the initial region, stress at specified compressive strains, and full curve characterization for design and QC.

Tip: Achieve true material response by ensuring platen parallelism and minimizing frictional constraint at the interfaces.

Industries & applications

Automotive

Engine mounts, bushings, NVH isolators. Monitor stiffness drift with temperature; document test conditions for correlation.

Infrastructure

Bridge bearings and pads. Prioritize accurate modulus and shape factor consistency for structural calculations.

Consumer goods

Footwear midsoles, appliance feet. Control rate and strain limits to avoid over-compression artifacts.

Medical

Elastomeric seals and cushions. Maintain clean platens and traceability for regulated environments.

Specimens

- Use cylindrical or prismatic specimens conforming to the standard's geometry and tolerances; document thickness and loaded area precisely.

- Condition specimens at target temperature/humidity; record dwell time and environmental parameters.

- Surface quality: ensure parallel, smooth loading faces; remove flash and avoid edge damage.

- Replicates: test sufficient specimens to capture batch variability (commonly n = 5).

Fixtures & platens

- Use hardened, flat compression platens with a verified parallelism; consider self-aligning upper platen for quick setup.

- Where friction affects results, use approved lubricants or low-friction interlayers as permitted; report choices in results.

- Apply centering aids to maintain coaxial loading and avoid tilting-induced non-uniform stress.

Instrumentation

- Load cell: select to operate typically within 10–90% of capacity for expected forces.

- Displacement/strain: use crosshead travel for global strain; for precision, add an LVDT/clip-on compressometer across the specimen.

- Data rate: at least 10 Hz; increase for rapid segments to capture curve shape accurately.

Procedure

- Measure specimen dimensions; compute initial loaded area and shape factor if applicable.

- Install platens; verify parallelism and alignment; position specimen centrally.

- Zero load and displacement; apply compression at the specified rate to the target strain or force.

- Record force–displacement continuously; unload as required by the method and document any hysteresis.

Calculations

- Compressive stress: s = F / A0 (force divided by original loaded area).

- Compressive strain: e = ?h / h0 (change in thickness over initial thickness).

- Compressive modulus: slope of the initial linear portion of the stress–strain curve.

- Stress at specified strains: report at defined compressive strains per method requirements.

Reporting

- Specimen geometry, conditioning details, and number of replicates.

- Platen type, alignment method, lubrication/interlayer usage.

- Test rate, strain limits, data sampling rate, and temperature/humidity.

- Results: modulus, stresses at specified strains, full curves; statistics (mean, SD, CV).

Recommended Testometric setup

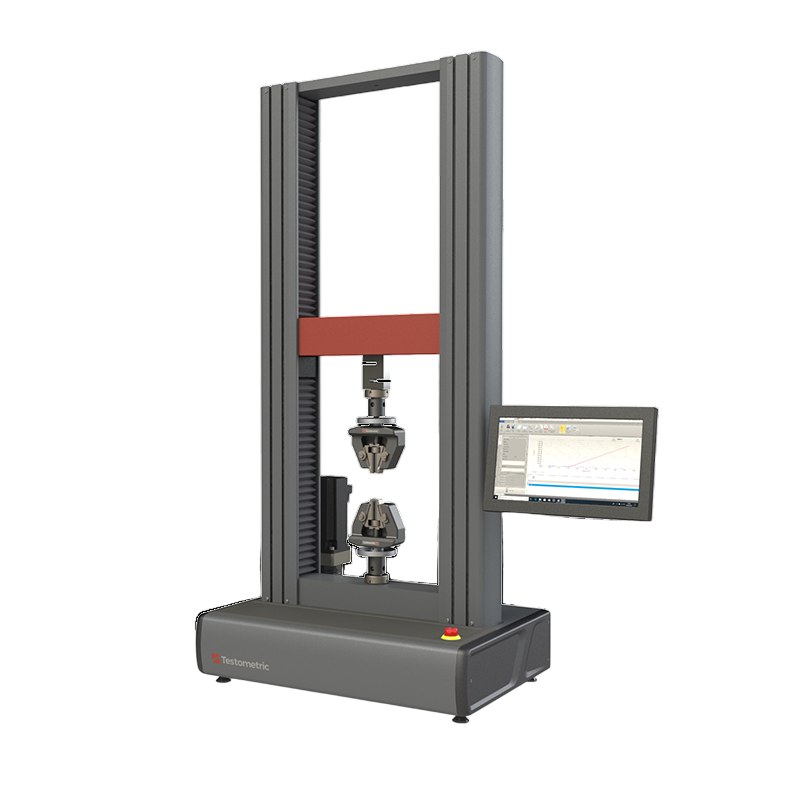

Frame

Testometric twin-column UTM with high-resolution control for steady-rate compression and excellent low-force sensitivity.

Compression platens

Precision-ground, parallel platens; optional self-aligning upper platen for fast, repeatable alignment.

Displacement measurement

LVDT/compressometer kit for direct specimen deformation measurement; synchronized with WinTest Analysis.

Software

WinTest Analysis with ASTM D575-91 method template, automated calculations, and compliant reporting.

- ±0.5% system accuracy with 0.000001 mm position control resolution for tight modulus calculations.

- 800% overload protection helps safeguard loadcells in compression with hard stops.

- Dual-station options, heavy-duty hydraulic/dual-cylinder pneumatic grips and a broad accessory ecosystem.

- Optional environmental chambers from -165°C to +300°C for temperature-dependent rubber behavior.

- High-rate data acquisition (500/1000 Hz) ensures smooth stress–strain curves.

- Fully supported in India by FITCO: installation, training, spare parts, after-sales service, and 2-year comprehensive warranty.

Best-fit models by force range

| Bench-top X-Series | Force capacity (kN) | Typical D575 use |

|---|---|---|

| X250-1 | 1 | Small rubber plugs, soft compounds, method development |

| X250-2.5 | 2.5 | General elastomers, QA screening |

| X250-5 | 5 | Elastomer components, pads, gaskets |

| X350-10 | 10 | Moderate-stiffness compounds and larger specimens |

| X350-20 | 20 | High-stiffness compounds; small bearing pads |

| X500-25 | 25 | Rubber blocks, foams with higher loads |

| X500-30 | 30 | Production QA for heavy elastomer parts |

| X500-50 | 50 | Thick rubber blocks; R&D on reinforced compounds |

| X500-100 | 100 | Large specimens; structural elastomer testing |

| Floor-standing XFS Series | Force capacity (kN) | When to choose |

|---|---|---|

| XFS-100 | 100 | Large travel/rigidity for big compression stacks |

| XFS-150 | 150 | Higher load bearings and pads |

| XFS-200 | 200 | Heavy industrial elastomer components |

| XFS-300 | 300 | Pilot plant and structural elastomer programs |

| XFS-500 | 500 | Very high load compression and fixtures |

| XFS-600 | 600 | Research labs with extreme force requirements |

| XFS-1000 | 1000 | Special projects and heavy engineering |

Notes: Travel, column spacing, and speed ranges vary by configuration. Contact FITCO India for a tuned setup, grip selection, and WinTest method templates.

FAQs

How many specimens?

Use a statistically meaningful number (commonly =5) to capture compound variability; increase when comparing process changes.

Why do curves show barreling?

Friction at platen interfaces constrains lateral flow, causing bulging. Use approved low-friction measures and report them.

Do I need a self-aligning platen?

For small, compliant specimens, it greatly reduces setup time and improves repeatability.

Related Standards

ISO 37

Tensile testing of vulcanized rubber – dumbbell specimens, grips, and strain measurement.

ASTM D412

Tensile properties of rubber – die C specimens, stress-strain, and elongation at break.

ASTM D2240

Rubber hardness testing – Shore A and Shore D durometer measurements.

Need Help with Rubber Compression Testing?

Our experts can help you select the right Testometric UTM configuration, compression platens, and test fixtures for your elastomer testing requirements. Get a personalized recommendation.