Description

Force Measurement

Universally Calibrated, better than Grade 0.5 EN 7500-1, DIN 51221 ASTM E-4. AFNOR A03-501. Range 0.4% to 100% minimum. Automatic identification of load cell. Resolution 1 part in 500000 with autoranging. Electronic load cell protection.

Extension Measurement

Full frame length to 0.001mm. Resolution 0.001 min. Accuracy 0.01mm. Absolute, relative and auxiliary modes mm, inch and percent. Programmable extension limits.

Speed Control

Drive system temperature and current protection. Positional jog speed 0.001mm/min to maximum. Speed setting increments 0.001mm/min.

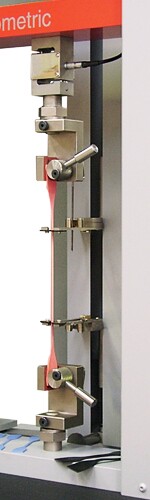

Load Frame

Rigid frame, using dual slide crosshead guidance system and rigid extruded support column. Frame stiffness 5kN/mm plus K factor facility built-in. Re-circulating ball screw with bellows. Electronic limit trips, total travel trips and customer programmable safety stops. Rubber mat front protection.

Software

Comprehensive winTest™ Analysis universal windows software covering tensile, compression, peel, shear, tear, cyclic, creep and multi stage testing. It includes a wide range of industry standard test methods and facility to create and store an unlimited number of further test methods. There is automated storage of all test data and ease of export to other software packages such as word, excel, access and SPC systems for enhanced report generation.