ISO 527-2 – Tensile Testing of Rigid & Semi-Rigid Plastics

Your comprehensive guide to ISO 527-2 testing requirements, specimen types, grip selection, strain measurement, test procedures, and calculations – optimized for Testometric UK universal testing machines.

Overview

ISO 527-2 specifies test conditions for determining tensile properties of rigid and semi-rigid plastics including injection molded specimens and machined bars. Key outputs include tensile strength, modulus of elasticity, elongation at break, and stress at specified strains. Success depends on correct specimen type, grip selection, strain measurement, and adherence to test speeds.

Tip: Use Type 1A specimens for injection molded materials and Type 1B for machined bars. Ensure proper conditioning and verify grip alignment before testing.

Industries & applications

ISO 527-2 is fundamental across industries requiring precise mechanical characterization of rigid plastics. Different sectors emphasize different properties based on application requirements.

Automotive

Interior trim, structural components: ABS, PC, PA, POM. Critical for impact resistance and dimensional stability under load.

Electronics

Housings, connectors: PC, PBT, PPS. Focus on modulus and strength for precise component fit and electrical insulation.

Medical devices

Device housings, surgical instruments: PEEK, PSU, PEI. Biocompatibility combined with high strength and chemical resistance.

Packaging

Rigid containers, closures: PET, HDPE, PP. Balance of strength, clarity, and barrier properties for food safety.

Common pitfalls

- Incorrect specimen geometry: Verify dimensions match Type 1A/1B requirements; poor machining creates stress concentrations.

- Grip slippage: Use appropriate jaw faces (serrated for hard plastics) and ensure adequate clamping force without crushing.

- Strain measurement errors: Verify extensometer gauge length and avoid clip-on devices that may slip during test.

- Test speed variations: Program correct crosshead speeds to achieve specified strain rates; monitor and adjust during test.

- Environmental effects: Control temperature and humidity; many plastics are sensitive to moisture content.

- Premature failure: Check for notches, scratches, or stress whitening that indicate material defects or handling damage.

Quick win: Always inspect specimens under good lighting before testing and reject any with visible defects or dimensional deviations.

Specimens & types

- Type 1A: Preferred for injection molded specimens (170mm overall length, 75mm gauge length)

- Type 1B: For machined test bars from sheet, rod, or tube

- Sub-sized types (1BA, 1BB, 5A, 5B): When material quantity is limited

- Conditioning: Stabilize at 23°C ± 2°C, 50% ± 5% RH for minimum 16 hours

- Surface quality: Smooth surfaces free from scratches, notches, or stress marks

Grip selection

- Pneumatic grips with pressure control for consistent clamping without crushing

- Jaw faces: Serrated for hard plastics, smooth for softer materials

- Alignment: Verify specimen centerline alignment to prevent bending stresses

- Clamping length: Ensure adequate grip engagement without affecting gauge section

Instrumentation

- Load cell: Sized for expected maximum force (typically 10-90% of capacity)

- Extensometer: Clip-on or non-contact with 50mm gauge length for modulus determination

- Crosshead displacement: High-resolution measurement for total elongation

- Data acquisition: Minimum 10 Hz sampling rate for accurate curve capture

Procedure

- Measure specimen dimensions at three points; record minimum cross-sectional area.

- Install specimen in grips ensuring proper alignment and gauge length.

- Attach extensometer for modulus measurement; set zero points for load and strain.

- Apply test at specified rate (1-10 mm/min typically); record complete stress-strain curve.

- Remove extensometer before specimen failure; continue to break or specified elongation.

Calculations

- Tensile strength: Maximum stress = F_max / A_0 (force divided by original cross-sectional area)

- Modulus of elasticity: Slope of stress-strain curve between 0.05% and 0.25% strain

- Elongation at break: (Final gauge length - Initial gauge length) / Initial gauge length × 100%

- Stress at specific strains: Force at specified elongation divided by original area

Reporting

- Specimen type, dimensions, conditioning details

- Test speed, grip type, extensometer specifications

- Environmental conditions during testing

- Complete results: strength, modulus, elongation; number of specimens tested

- Statistical analysis: mean, standard deviation, coefficient of variation

Recommended Testometric setup

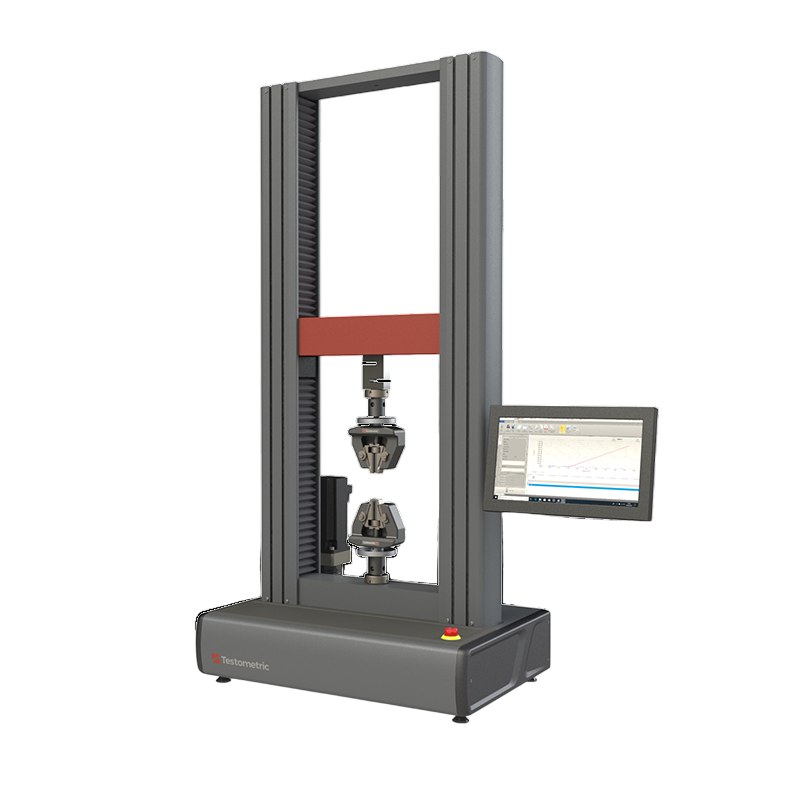

Testing machine

Testometric X-Series (X350/X500) with 10–50 kN capacity; servo-controlled crosshead with high-resolution position feedback for precise speed control.

Gripping system

Heavy-duty pneumatic grips with pressure regulation; interchangeable jaw faces for different materials and surface textures.

Strain measurement

Clip-on extensometer with 50mm gauge length; automatic removal feature to prevent damage during specimen failure.

Software

WinTest Analysis with pre-configured ISO 527-2 methods; automatic calculation of all required properties and report generation.

- ±0.5% system accuracy and 0.000001 mm position control resolution for precise modulus calculations.

- High-rate data acquisition (500/1000 Hz) to resolve yield and necking events.

- 800% overload protection on loadcells; 900+ grip options including wedge and pneumatic types.

- Environmental chambers -165°C to +300°C for temperature-dependent behavior studies.

- FITCO India support: installation, operator training, spares, after-sales service, 2-year comprehensive warranty.

Model suggestions for rigid & semi-rigid plastics

| X-Series model | Capacity | Typical use |

|---|---|---|

| X350-10 | 10 kN | General tensile on rigid plastics, modulus and yield studies |

| X500-25 | 25 kN | Filled/FR materials; higher force margin for fixtures |

| X500-50 | 50 kN | Thick sections, composites, and R&D with accessories |

| Accessory | Option | When to choose |

|---|---|---|

| Grips | Wedge or pneumatic, serrated jaws | Rigid plastics requiring high clamping without slip |

| Extensometer | Clip-on, 50 mm gauge | Standard modulus/yield determination per ISO 527-2 |

| Extensometer | Video/non-contact | Brittle or high-elongation materials; avoid mass loading |

| Chamber | -165°C to +300°C | Characterization at non-ambient temperatures |

Specifications vary by configuration; contact FITCO India for a tuned ISO 527-2 method and accessory set.

FAQs

Type 1A vs 1B specimens?

Type 1A for injection molded parts preserving processing effects; Type 1B for machined specimens when molding isn't possible.

Modulus calculation range?

Calculate between 0.05% and 0.25% strain per ISO 527-2; ensure linear region and adequate data points.

Test speed selection?

Use 1-10 mm/min for most materials; slower speeds for brittle plastics, faster for tough materials within standard limits.

Conditioning requirements?

Standard conditions: 23°C ± 2°C, 50% ± 5% RH, minimum 16 hours; some materials require special conditioning.

Related Standards

ISO 527-3

Tensile testing of films and thin sheets – for flexible packaging and membrane materials.

ISO 178

Flexural properties of plastics – three-point bending for modulus and strength.

ASTM D638

US equivalent for tensile testing of rigid plastics – specimen and procedure differences.

Need Help with ISO 527-2 Testing?

Our experts can help you select the right Testometric UTM configuration, grips, and extensometers for your specific plastic testing requirements. Get a personalized recommendation.