Description

Specifications

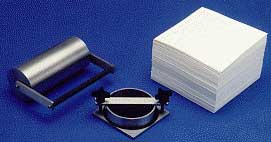

The Gurley Model 4301 Permeometer measures the porosity or air permeability of materials where air flow is an important characteristic relative to their use. These materials might be non-woven or woven textiles, filter and tissue papers, facial tissues, paper and cloth felts, some types of blotting, saturating and absorbent bag papers as well as wire meshes.

The Permeometer is the standard instrument for measuring high levels of air-permeability or air-resistance as recommended in various test methods published by ASTM, TAPPI and ASA. Its unit of measurement is cubic feet of air per minute per square foot at 0.5 inches of water pressure drop.

The Gurley Model 4301 is used throughout the textile and general manufacturing industries and is considered the instrument of choice due to its simplicity of loading samples, ease of use, portability and life expectancy in comparison to competitive models. Its procedure is non-destructive and its design allows the testing of long samples, up to six inches in from any edge.

Applications

- To determine ability for material to pass air as a primary user requirement (such as parachute cloth or vacuum cleaner bags).

- To evaluate materials used as filters.

- Aid in determining coolness or warmth (as insulation values) in clothing.

- To predict probable coating penetration.

- To measure retention of filters, sizing or scratch after laundering or use.

- To aid in prediction of water-resistant properties.

- To measure the effect of treatments on porosity, density, nap or other material properties.

- Allows fast & easy quantitative measurement of variables in production not detectable by appearance or other methods.

- a non-destructive test to accurately delineate & quantify differences in materials and treatments.

FEATURES :

- Quick & easy sample loading

- Rapid test cycle

- Excessive clamping pressure unnecessary

- Portable & rugged design

- Complies with TAPPI, ASTM, & ASA standards