Description

All Genuine GurleyTM bending resistance/stiffness testers are based on the same physical principle. each instrument consists of a balanced pendulum or pointer which is center-pivoted and can be weighted at three points below its center. The pointer moves freely in both left and right directions on cylindrical jewel bearings which make the mechanism highly sensitive even to light-weighted materials.

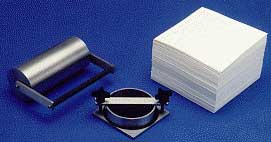

A sample of a specific size is attached to a clamp (parallel for flat sheet materials and tubing clamp for catheters, etc.), which in turn is located on one of several positions on a motorized arm which also moves left and right. The bottom 0.25″ of the sample overlaps the top of the pointer (a triangular shaped “vane”). During the test the sample is moved against the top edge of the vane, moving the pendulum until the sample bends and releases it.

On manual/motorized models, the technician must observe the test to discern the maximum displacement of the pointer on the scale. The value (for flat sheet materials) reached is then located on a conversion chart to arrive at the appropriate bending resistance/stiffness measurement.

On digital models, the point of release is automatically measured by an optical encoder and displayed on a digital readout. this readout continuously displays readings from tests performed in both the left and right directions. In addition, the on-board microprocessor automatically computes and displays the average of left and right stiffness data after each measurement is performed. When measuring Flat Sheet samples, the 4171S simultaneously calculates, and displays, force ( milligrams ) which then can be multiplied by a constant for bending moment (gram-centimeters or millinewton-meters). For tubing, we recommend using the scale reading only for samples of similar dimensions and material.

A complete set of accessory weights is included with every instrument as well as a calibration strip. Whether you are testing membranes or tubing, the Gurley Bending Resistance/Stiffness Tester offers you the greatest range of possibilities.

Motors are regularly supplied for use on 115 VAC, 50 or 60 Hz. A transformer may be obtained for use on higher voltages.

Cylindrical jewel bearings make the vane highly sensitive even to very lightweight materials. The instrument is not recommended for heavy limp materials.

Four leveling screws and a circular spirit level are used to make the base level. The loading weights, in two sections, screw together on the pointer or are mounted on a bracket when not in use.

Dimensions: Height 20″, base 11 1/2″ x 9 1/4″ clamp

General Manufacturing Control

Quality in many products depends on their degree of flexibility or stiffness. Packaging, playing cards, boxboard fabrics, containers, wire, tubing, many plastic and metal parts are examples. Specifications for these and others can be established with this instrument.

Medical Manufacturing

Comfort relative to material flexibility is an important part of the design and manufacturing process. Adhesive bandages, laminated or coated materials and supplies are all evaluated with a Genuine GurleyTM bending resistance/stiffness tester.

Chemical Treatments

The effect of stiffening (as with starch or plastic), or softening (as with glycerin or oils) can be studied with the Gurley bending resistance/stiffness tester. Makers or users of gums, lacquers, varnishes, latex, plastics, waterproofing compounds, etc., can be measure the effect of such treatments.

Textile Testing

Technicians may better quantify the “handle” or “feel” of certain fabrics as well as test for the effect of laundering, filling, starching or coating. Minute weave differences as well as weights may also be evaluated.

Research

Problems and analysis involving stiffness measurement in product development and quality control are easily evaluated the Gurley bending resistance/stiffness tester clearly shows differences which would be hard to distinguish otherwise. Its unequaled range and capacity make it an indispensable instrument in many industries.

NOW OFFERING GURLEY, TABER & INTERNATIONAL ENGINEERING VALUES

Genuine GurleyTM digital bending resistance/stiffness testers output in Gurley units (milligrams) can be converted by hand to grams centimeters and millinewton meters, making them equivalent to Taber products, TAPPI, ISO and worldwide standards. Information on equivalency is available from your sales person.

Model 4171S Digital Bending Resistance/Stiffness Tester with parallel clamp and RS-232 serial communications port

* All flat sheet models meet industry standards TAPPI #T543 and ASTM D6125-97.

Medical Manufacturing

Comfort relative to material flexibility is an important part of the design and manufacturing processes. Catheters and tubing, guide wires, artificial parts and supplies are all evaluated with our Model 4171DT or 4171ET Bending Resistance/Stiffness Testers. Implants and products used in invasive and non-invasive procedures can also be tested.

Chemical, Temperature and Other Treatments

The effect of softening, stiffening, radiation and environmental exposure on catheters and other materials be studied with the Gurley bending resistance/stiffness tester.

Research

Problems and analysis involving stiffness measurement in product development and quality control are easily evaluated the Gurley bending resistance/stiffness tester clearly shows differences which would be hard to distinguish otherwise. Its unequaled range and capacity make it an indispensable instrument in many industries.

Gurley Precision Instruments can design custom applications such as this toothbrush holder. Call for more information.

ADVANTAGES

Durometer Comparison. The Gurley Bending Resistance/Stiffness Tester provides several advantages over the sole reliance on durometer readings as an indication of stiffness.

Testing around Longitudinal Axis. Measuring tubing stiffness at various points around the longitudinal axis can indicate differences in bending resistance/stiffness due to structure, treatment, composition or defects. These differences can be observed and enable the technician to isolate such areas on the specimen.

Testing of Manufacturing Processes. A Gurley tubing tester enables customers to determine the effects of the following factors on bending resistance/stiffness:

Coatings, Multi-wall constructions, Co-extrusions, Chemical composition, Inserts, Multi-lumen construction, Radiation, Environmental exposure

Range of Materials Tested. Using the precision tubing clamp assembly or the parallel clamp, the instrument can accommodate:

Rods & wires, Monofilament, Finished products, Flat sheet materials to 0.25″ thick, Tubing, oval, polygon or asymmetrical cross sections, single or multi-lumen to 0.62″ OD

Model 4171T Digital Bending Resistance/Stiffness Tester with parallel clamp and tubing clamp assemblies; RS-232 communications port, parallel and tubing clamp assemblies.

Both of above models include one each:

- Parallel clamp #284-66

- Clamp Frame #CX00910

- Specimen insert #BX01222

- Holder #BX01220

- Accessory box w/insert #CX01019