Introduction: The Critical Role of ISO 527-3 in the Plastics Industry

In the world of polymer science and manufacturing, precision is paramount. For industries relying on plastic films and thin sheets—from flexible packaging and medical devices to automotive interiors and consumer electronics—understanding a material's mechanical properties is not just a quality check; it's a fundamental requirement for safety, performance, and commercial success.

ISO 527-3: "Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets" is the globally recognized standard that provides the definitive framework for this critical analysis. This standard outlines the precise methodology for measuring the tensile properties of plastic films and sheets less than 1 mm thick. Adherence to ISO 527-3 ensures that results are consistent, repeatable, and comparable across laboratories and supply chains worldwide.

Why Choose Testometric UTMs for ISO 527-3?

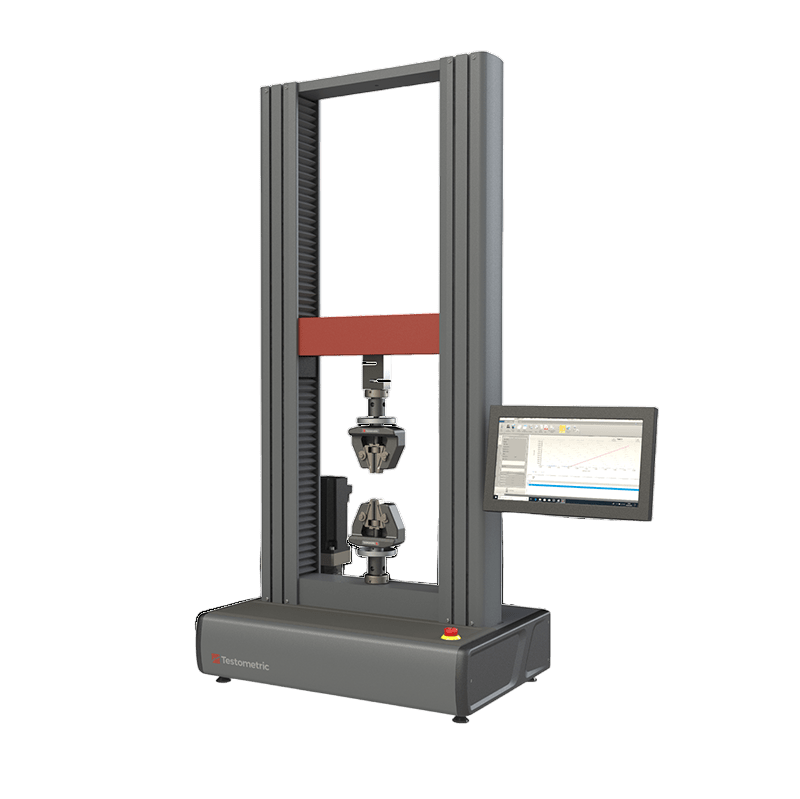

Achieving true compliance and generating reliable data is impossible without the right equipment. This is where Testometric Universal Testing Machines (UTMs), supplied in India by industry leader FITCO India, become indispensable. A Testometric UTM is not just a machine; it is a complete, precision-engineered solution designed to meet and exceed the stringent demands of ISO 527-3.

This comprehensive guide will delve into the technical specifics of ISO 527-3 and demonstrate why a Testometric system is the ultimate tool for flawless execution of plastic film testing protocols.

Deconstructing ISO 527-3: Key Technical Requirements

ISO 527-3 builds upon the general principles of ISO 527-1 but provides specific parameters tailored to the unique challenges of testing thin, flexible materials.

1. Scope and Key Properties Measured

The standard is exclusively for plastic films and sheets under 1mm in thickness. It is designed to determine several critical tensile properties:

- Tensile Strength at Yield and Break: The maximum stress a material can withstand before permanent deformation (yield) or fracturing (break).

- Tensile Modulus (Young's Modulus): A measure of the material's stiffness or resistance to elastic deformation.

- Elongation at Yield and Break: The percentage increase in length at the point of yield and fracture, indicating the material's ductility and stretchability.

- Strain: The deformation of the material in response to stress.

- Poisson's Ratio: The ratio of transverse strain to axial strain (optional but crucial for advanced analysis).

2. Specimen Preparation and Types

Accurate results begin with correctly prepared specimens. ISO 527-3 specifies several specimen types, with the most common being:

| Specimen Type | Shape | Primary Use | Key Features |

|---|---|---|---|

| Type 2 (preferred) | Dumbbell-shaped | Quality control | Easier to produce and handle |

| Type 1B | Dumbbell-shaped | Quality control | Alternative to Type 2 |

| Type 3 | Rectangular strips | High elongation materials | Straight-sided specimens |

Critical Success Factor

The integrity of the specimen is vital. Any nicks, uneven edges, or surface imperfections can create stress concentrations and lead to premature failure, invalidating the test results. Testometric UTMs provide specialized pneumatic grips designed specifically for delicate film handling.

3. The Crucial Role of Test Speed and Control

ISO 527-3 mandates specific, constant rates of crosshead separation (test speeds) to ensure comparability of results. The required speed depends on the material's properties, particularly its elongation at break. This demands a testing machine with exceptional speed control.

This is a core strength of Testometric UTMs. Powered by a high-resolution digital AC servo drive and a maintenance-free brushless servo motor, Testometric machines offer 23-bit positional control. This translates to a positional resolution as fine as 0.000001 mm (1 nanometer) on benchtop models.

4. The Non-Negotiable Need for Accurate Strain Measurement

Perhaps the most critical—and challenging—aspect of ISO 527-3 is accurate strain measurement. Using crosshead travel alone to measure strain is not compliant for determining tensile modulus and often inaccurate for other properties due to potential specimen slippage in the grips.

The standard requires the use of an extensometer. For delicate plastic films, traditional clip-on extensometers can be problematic as their weight and knife-edges can damage the specimen or induce premature failure.

The Testometric Solution: Advanced Video Extensometry

Testometric offers a state-of-the-art non-contact Video Extensometer. This system uses a high-resolution digital camera to track two small marks on the specimen.

- Zero Interference: It applies zero physical contact or weight to the specimen, making it the perfect solution for delicate films and high-elongation materials tested under ISO 527-3.

- Unmatched Accuracy: It measures strain directly from the specimen's surface, providing highly accurate data for modulus calculation and elongation at break, even for materials that stretch over 1000%.

- Digital Image Correlation (DIC): Advanced DIC capabilities allow for full-field strain mapping, providing insights far beyond what a traditional extensometer can offer.

The Ultimate Solution: Testometric UTMs for ISO 527-3 Compliance

While any UTM might claim to perform a tensile test, a Testometric machine is specifically engineered for compliance, repeatability, and ease of use.

The Perfect Force Range: Low-Force Precision Models

Testing thin plastic films typically requires low force capacities. The Testometric X250 and X350 series benchtop UTMs are perfectly suited for ISO 527-3 applications, offering force ranges from 1kN to 20kN.

| Feature | Specification | Benefit for ISO 527-3 |

|---|---|---|

| Load Cell Accuracy | ±0.5% of reading | Precise measurement of low forces |

| Resolution | 1/1000th of capacity | Accurate modulus calculation |

| Overload Protection | 800% capacity | Equipment protection |

| Position Resolution | 0.000001mm | Precise speed control |

Essential Grips and Fixtures for Flawless Film Testing

How you hold the specimen is as important as how you pull it. Improper gripping leads to slippage or jaw breaks—the most common sources of invalid ISO 527-3 tests.

- Specialized Pneumatic Film Grips: Testometric offers a wide range of grips, with pneumatic vice grips being the ideal choice for films. They provide consistent, adjustable clamping pressure across the entire grip face.

- Rubber-Faced Jaws: These interchangeable jaws prevent damage to the delicate film surface and provide excellent friction to eliminate slippage, a critical factor for high-elongation materials.

WinTest™ Analysis Software: Streamlining ISO 527-3 Testing

The power of Testometric hardware is fully unlocked by the intuitive WinTest™ Analysis Software. This comprehensive software package turns a complex testing procedure into a streamlined, automated process.

Key WinTest™ Features for ISO 527-3

- Pre-Loaded Standards: WinTest™ comes with a vast library of pre-configured test methods, including ISO 527-3. Simply select the standard, and the machine parameters are automatically set up.

- Automated Calculations: The software automatically calculates all key properties required by the standard: Tensile Strength, Tensile Modulus, Elongation at Break, Yield Point, and more.

- Real-Time Graphing: Watch the stress-strain curve develop in real-time, providing immediate visual feedback on the material's performance.

- Professional Reporting: Generate comprehensive test reports at the click of a button, complete with graphs, results, statistics, and company branding.

- 21 CFR Part 11 Compliance: For medical and pharmaceutical applications, the software is available with FDA-compliant features.

Step-by-Step: Performing an ISO 527-3 Test with a Testometric UTM

- Specimen Preparation: Cut your film specimens to the dimensions of Type 2 or Type 3 using a precision cutter. Condition them as required by the material specification (e.g., 23°C and 50% RH).

- System Setup: Power on the Testometric UTM. In the WinTest™ software, select the pre-configured ISO 527-3 test method.

- Mount Specimen: Open the Testometric pneumatic grips using the footswitch. Carefully align and clamp the specimen, ensuring it is vertical and not twisted.

- Attach Extensometer: If using a clip-on, attach it to the gauge length. If using the Testometric Video Extensometer, ensure the marks are in the camera's field of view.

- Run the Test: Press the start button. The machine will automatically apply a preload, zero the sensors, and begin the test at the exact speed specified by ISO 527-3.

- Data Acquisition: The system will capture thousands of data points for force, position, and strain in real-time. The test automatically stops upon specimen break.

- Analysis & Reporting: WinTest™ instantly calculates all results and plots the stress-strain curve. Save or print your complete, compliant test report.

FITCO India: Your Partner for Compliant Material Testing in India

As the premier distributor of Testometric in India, FITCO India provides more than just a machine. We provide a complete testing solution backed by unparalleled expertise and support.

Why Choose FITCO India?

- Expert Consultation: Our team of technical experts will help you configure the perfect Testometric UTM, grips, and extensometry package specifically for your ISO 527-3 testing needs.

- Trusted by Industry Leaders: We are the trusted partner for some of India's most demanding organizations, including ISRO, Reliance Industries, Aditya Birla Group, and Abbott.

- Comprehensive Support: We provide professional installation, on-site training, NABL-traceable calibration services, and ongoing technical support to ensure your laboratory operates at peak efficiency.

- Complete Portfolio: Beyond tensile testing, FITCO India offers a full range of material testing equipment, including Melt Flow Indexers (from Dynisco), Permeation Analyzers, and more.

Conclusion: Achieve Certainty with Testometric and FITCO India

ISO 527-3 is the cornerstone of quality assurance for plastic films and sheets. Attempting to meet its requirements with inadequate equipment leads to inconsistent results, product failures, and commercial risk.

By choosing a Testometric Universal Testing Machine, you are investing in certainty. You gain a system engineered for the highest levels of precision, powered by software that automates compliance, and supported by the deep technical expertise of FITCO India.

Ready to Upgrade Your Testing Capabilities?

From the 1kN X250 series to the most powerful floor-standing models, every Testometric UTM embodies over 50 years of British engineering excellence. Stop guessing. Start testing with confidence.